I will try my best to explain how it is cut.First what you want to acheive is to remove the part of the thread which is usually a small fin on the turned 45 degree angle portion of the part blank up to where it is a full profile 60 degree thread form.To do this you use a grooving tool after you are done with the threading cycle. First off you must calibrate your threading and grooving tools to the face of the part (or zero.This is where an important trick lies hidden. The center or tip of the threading tip has to be calibrated so it is equal to the leading edge of the groove tool and the groove insert must be as wide or wider than the base of the thread form (an 1/8" wide insert will work up to 8 pitch. etc) Lets say you are doing 10 pitch threads 1" thread length. Now with your regular threading cycle when you program your length you will get 1 full inch of thread and your first full thread length will be z-.100" (a starting length to be deburred) Now program your grooving tool(also in the same threading cycle as used to thread with) to a depth of z-.100" and you are starting to get a deburred thread. You will only need a couple of deburring passes to remove the burr (so play with the starting x value). But there is more to explain !! Spindle rpm and the machines rapid traverse rate will determine the amount of angle of ramp on the deburred thread. The machines rapid rate will stay constant so for a squarer ramp run slower rpms and a tapered ramp more rpms. Only one more tip if after calibrating the tools you have to adjust the z length of cut you must offset the z length equally on both tools.

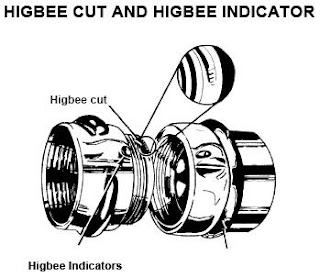

Not an easy operation to describe with just words and no pictures.We normally leave a 45 plus a little bit of the minor diameter to the + side of the start thread but the higbee cut looks WAY better. might be a tricky deal on a manual lathe with no stop mechanism but Looks like cake on cnc. I looked around the shop and found a coupler that shows exactly what it should look like.Now ..... if I can just make this link work!! http://photos.msn.com/myfiles/folderview.aspx?Folder=4gPozhciq6ZTdypEPFXEQi ctJ*RhGuXgXweAIQIykiw%24 (http://photos.msn.com/myfiles/folderview.aspx?Folder=4gPozhciq6ZTdypEPFXEQictJ*R hGuXgXweAIQIykiw%24)

I have found the G32 threading cycle to be perfect for stuff like this. G32 allows you to control the tool anyway you want to under a threading feed. In the manual for my Haas SL-30 the example is a continuous thread that goes from straight to tapered, then back to straight (I'd be interested to see the nut for this screw). With G32 you can change the vary the pitch while threading. I can't think of an application for this, but it might come in handy sometime. We use this cycle all the time for higby ends, and for taking the spring out of long threaded parts. In other words, you can program a thread that moves the tool into the piece at a variable taper rate to compensate for deflection.

I have found the G32 threading cycle to be perfect for stuff like this. G32 allows you to control the tool anyway you want to under a threading feed. In the manual for my Haas SL-30 the example is a continuous thread that goes from straight to tapered, then back to straight (I'd be interested to see the nut for this screw). With G32 you can change the vary the pitch while threading. I can't think of an application for this, but it might come in handy sometime. We use this cycle all the time for higby ends, and for taking the spring out of long threaded parts. In other words, you can program a thread that moves the tool into the piece at a variable taper rate to compensate for deflection.

Source - Internet.

Can you give cycle suitable for Siemens controller?

ReplyDeleteRegards,

Kedar Lagoo